Supercharging the Battery: The Pursuit of Safety and Power

Batteries have the power to transform our lives — they already have. First developed in the 1970s, lithium-ion batteries have expanded into a $7 billion industry. They power our phones, computers, cameras, radios, e-cigarettes, tools, and wheelchairs. They power our electric cars. They could even power electric planes. Lithium-ion batteries have the potential to unseat fossil fuel-based technologies and drive sustainability efforts to transition to clean energy sources. But they haven’t. Not yet, at least.

Why?

Despite expansions and molecular advancements, lithium-ion batteries remain expensive, with unmet energy potentials. For decades, battery technology has been unable to meet growing demands for sustainable solutions.

In 2010, production of lithium-ion batteries cost $1,200 per kWh. By 2018, it dropped down to $175 per kWh. Nevertheless, manufacturing costs of battery-operated devices, specifically motor vehicles, continue to drive prices higher than similar gas-powered models. For the consumer, savings on gasoline don’t offset the higher upfront cost of an electric car. According to the US Department of Energy, once battery costs fall below $125 per kWh, owning an electric car will be cheaper than a gas-powered alternative.

We need safer, more powerful, and energy-dense batteries – that are also cheap.

To make bold advancements in renewable energy technology, batteries need to produce bold power potentials. In order to produce enough power to launch a commercial jet, or even to maintain a stable battery life that doesn’t worsen with each recharge (for smartphones and laptops), scientists must work to increase the energy potential of lithium-ion batteries.

But the molecular tinkering involved in trying to increase energy density while simultaneously decreasing cost plays a dangerous game. While trying to improve one trait (like power), scientists often sacrifice another (like safety). The 2016 Samsung smartphone scandal brought battery safety concerns to the public’s pockets. The resulting recall of the Galaxy Note 7, which started exploding and catching fire, cost the company $5.3 billion.

In order to displace our current dependence on unsustainable energy sources, like oil, natural gas, and uranium, we need clean, renewable energy sources that are powerful enough and cost-effective enough to compete in the marketplace. We need energy sources that are not dependent on fluctuating environment conditions – a windy day, the angle of the sun. We need energy sources that can be stored and tapped in any place, at any time.

“Across the industry, the ‘gating factor’ for sustainability is the recognized need for Lithium-ion Battery technologies to demonstrate increased Safety, Capacity and Cycle Life, without trade-offs on Power, Weight, or Cost per kWh.”

Chris Thorne, BROADLINE CAPITAL

Powermers has developed the world’s first carbon-free lithium-ion battery. It calls itself a disruptive innovator, creating a higher-energy, longer-lasting battery that is also significantly safer and cheaper than alternatives. “No single Lithium-ion Battery technology development in recent history has increased Safety, Capacity and Cycle Life without sacrificing other performance attributes such as Power, Weight, or Cost per kWh…until now.” (Chris Thorne, Broadline Capital)

As compared to traditional lithium-ion batteries, Powermer batteries improve both safety and specific energy performance. This increased performance has been validated by both the U.S. Army Corps of Engineers’ Battery Testing Facilities (CERL) in Champaign, Illinois, and the Ohio State University’s Center for Automotive Research in Columbus, Ohio.

As Altru CEO and Co-Founder Brett Johnson says, “Powermers presents a really exciting and important technological advance. The big problem for Sustainability is energy storage – if we can’t store extra energy from solar and wind power, then we will continue to be tied to fossil fuels.

How have they done it?

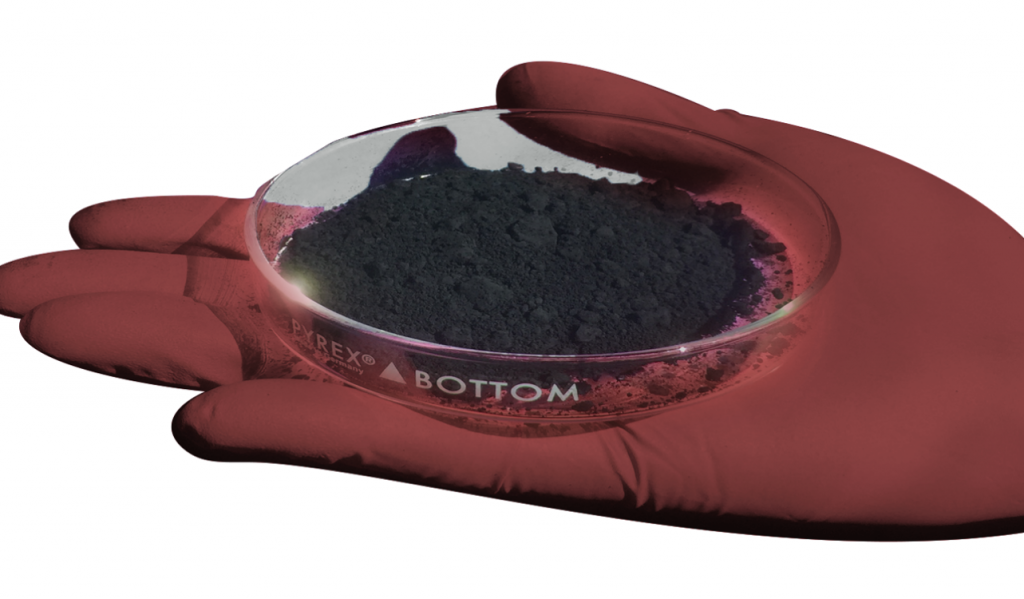

Powermers has eliminated Carbon and PDFV binders from the cathodes of conventional lithium-ion batteries. Using their patented polymer technology platform and electro-conductive advanced materials, Powermers removes the deadweight from traditional battery mechanisms to increase performance and specific energy by 10-15%.

The result: a game-changing increase in the percentage of active material in the battery’s cathode.

“Among the objectives we set when developing Powermers’ technology was not only to make batteries Safer and to deliver more Energy Capacity, but also to make sure that the technology could be seamlessly incorporated into the existing Li-ion Manufacturing Process, and to reduce the Manufacturing Cost per kWh.” – Sam Kogan, PhD (Powermers CEO)

According to the company, the removal of carbon dramatically mitigates the thermal runaway risk relating to gas build-up and combustion and eliminates the possibility of electrolyte decomposition. The batteries are more mechanically stable, and cheaper to produce. Powermers batteries have the power to reset industry standards of safety, efficiency, and innovation.

Powermers is currently working with strategic partners and corporate acquirers (battery manufacturers like Panasonic, Samsung and Tesla), to incorporate their patented polymers into various battery products. By harnessing this novel technology, companies can begin to evaluate the resulting impact differential.

With this technological advance, the future of electric planes comes one step closer.